The ArmorPoxy Metal and Steel Industrial Coating is a high performance, one component moisture cured polyurethane coating designed to provide an exceptional protection for steel and metal surfaces in demanding outdoor environment. The coating works exceptionally good with primer and can standalone for durable aluminum finish.

This coating is advanced formula provided for powerful resistance again corrosion, abrasion and other elements to bring sustainability and durability. In this guide, ArmorPoxy expert will install coating for your easy application at home in step by step process.

Step 1: Prepare Surface

-

Clean the surface thoroughly to remove dirt, grease, oil or rust using a degreaser or industrial cleaner.

-

Use a wire brush, sandpaper or a power grinder to remove loose rust and old paints.

-

Ensure the surface is fully dry before applying the coating

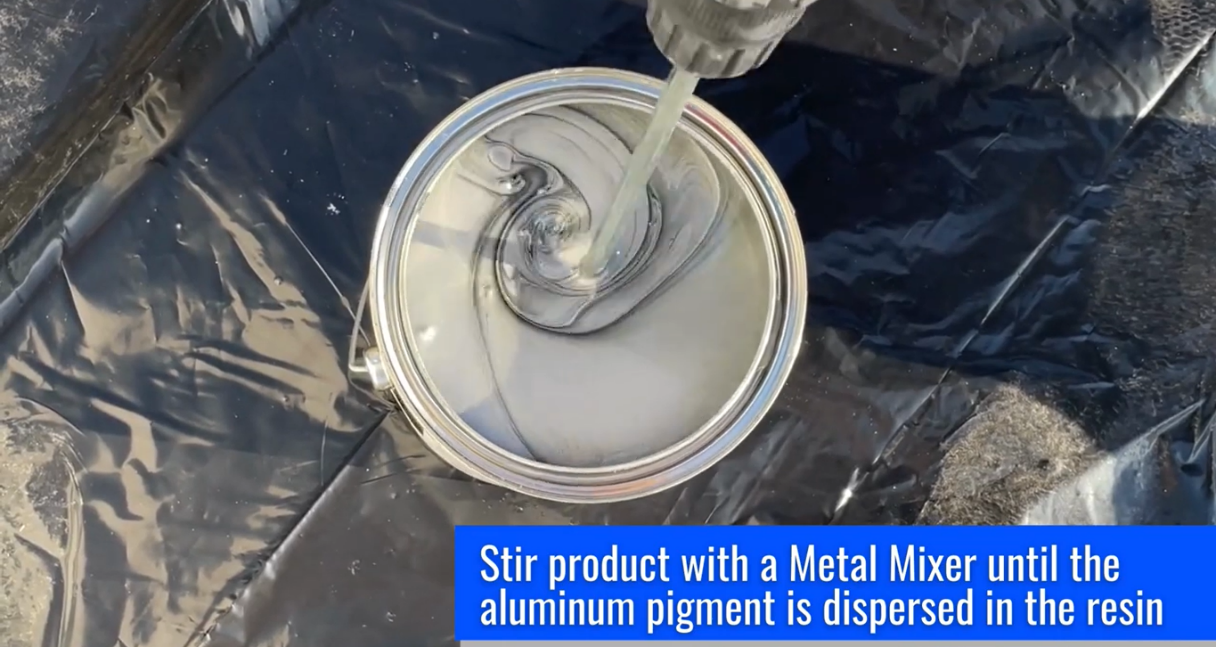

Step 2: Mixing the Coating

-

ArmorPoxy coating is a two-part epoxy or urethane system, mix components according to the specified ratio.

-

Stir thoroughly to ensure a uniform consistency.

-

Allow the mixture to sit (induction time) if required.

Step 3: Application

-

By Roller: Use a high-quality, solvent-resistant roller for even application.

-

By Brush: Ideal for edges, corners, and touch-ups.

-

By Spray: Use an airless sprayer for a smooth, professional finish.

Step 4: Drying & Curing

-

Allow the first coat to dry according to the product's recommended time.

-

Apply a second coat after 1-2 hours for better coverage and durability.

-

Full curing may take 2 to 6 hours depending on temperature and humidity

-

The coating can be applied in temperatures from 18F to 140F.

Step 5: Maintenance & Longevity

-

Once cured, the coating provides a durable, chemical-resistant surface.

-

Regularly clean with mild detergents and avoid harsh chemicals to prolong its lifespan.