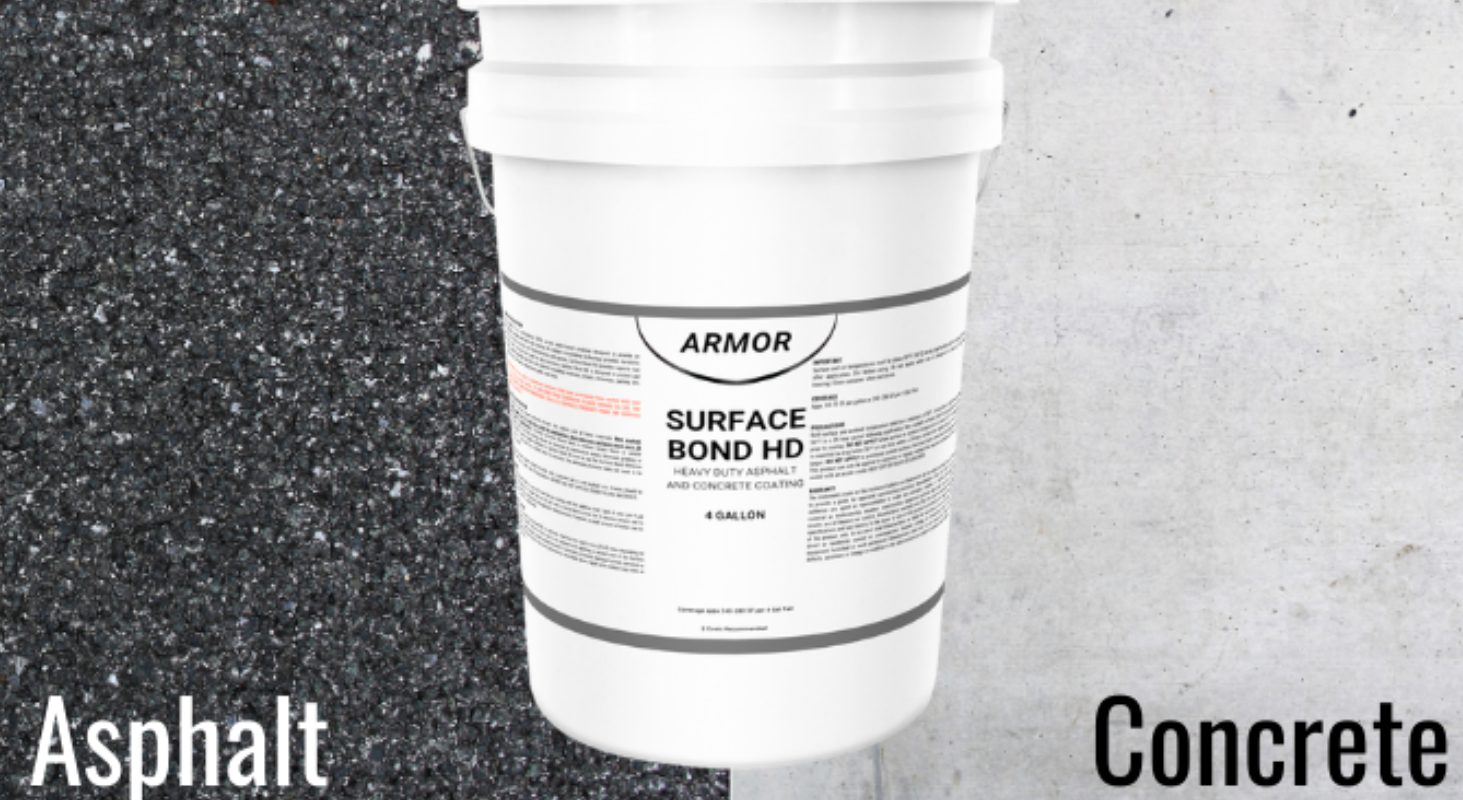

Surface Bond

Surface Bond: is an innovative coating that was designed for large and small projects. Restore your asphalt or concrete with Surface Bond. It's vehicle rated and DIY friendly. With its advanced formula, Surface Bond offers unmatched strength, protection, and longevity for concrete and asphalt surfaces.

Surface Bond is a cutting-edge surface coating solution developed to restore and protect both large-scale and smaller projects involving asphalt and concrete surfaces. With its innovative formula, Surface Bond is not only vehicle-rated, making it ideal for driveways, parking lots, and roadways, but also DIY-friendly, making it easy for homeowners and professionals alike to apply. This versatile product offers exceptional durability, safeguarding surfaces from wear and tear, harsh weather conditions, and chemical exposure.

Surface Bond’s advanced formula increases the strength of existing concrete and asphalt surfaces, prolonging their lifespan while maintaining a clean and fresh appearance. It resists cracking, fading, and damage caused by UV rays or heavy traffic, ensuring long-lasting protection. Ideal for both residential and commercial applications, Surface Bond simplifies the restoration process while delivering professional-grade results. Whether you’re resurfacing a driveway, patio, or sidewalk, Surface Bond is the reliable solution for durable, strong, and appealing surfaces.

Extremely Durable & Resilient Outdoor Coating

High performance industrial grade coating used by thousands of municipalities and commercial customers for parking lots, playgrounds, driveways, bike lanes, pedestrian and vehicular areas, pedestrian malls, and traffic flow pattern marking. Can be applied on asphalt and concrete substrates.

Easy to apply application. Open, mix in the Surface Bond HD color pigment, and roll out! This unique heavy duty coating rolls on like paint, but has 20x the performance and life span. It’s low VOC, water-based formulation has almost no odor or toxic chemicals and is safe to use in all 50 states. It meets all USA environmental requirements. Surface Bond HD helps to rejuvenate concrete and asphalt surfaces, making them look ‘like new’, and adding significant life and protection from the elements. Surface Bond HD uses special nanotechnology bonding agents to assure a firm bond to your surface and long life. Fully UV protected from the elements and can withstand rain, snow, hail, salt, chemicals, fuels, oils, etc.

Fast drying times allow you to get back on to your floor the same day! This products reauires 2X coats. Recoat time is 30 mins -1 hour after initinal coat and will vary depending on temparetue and RH. Allow 8-12 hours for full cure (Cooler temperatures may affect cure times). Wait 24 hours for vehicle traffic.

Each Kit includes 4 Gal of Surface Bond HD shipped in a 5 Gal mixing bucket and 1 pint of color pigment. Mix each pint of pigment into the 5 Gal pail for appx 5 minutes. Use our Surface Bond HD Pail Mixer or any standard metal sprial mixer or mud mixer. Apply the first coat by roller or spray. This product has a long working time unlike epoxy. Standard nap rollers may be used to apply or use our Surface Bond HD Textured Roller to create an “orange peel” effect. This product can also be squeegeed and backrolled to help faciliate spreading of material. If using squeege ensure to use a flat squeegee. Coverage is 60-70 sq ft/gal (240-280 square feet per pail/coat). Minimum of two coats is required. Please note that during the initial coat your coverage will be lower due to the absorption of the surface, but subsequent coat coverage will be higher since the surface is now sealed. Additon of additional coats beyond two coats will add life span and durability. A maximum of 4 coats can be applied. Coverage may vary based on surface.

Benefits of Surface Bond:

- Durability and Strength: Surface Bond’s advanced formula significantly enhances the durability of asphalt and concrete surfaces, providing long-lasting strength and protection against daily wear and tear, including heavy vehicle traffic.

- Weather Resistance: The coating is designed to withstand harsh environmental conditions such as extreme temperatures, UV rays, rain, and snow, preventing cracking, fading, and other damage caused by weathering.

- Vehicle Rated: Surface Bond is vehicle-rated, making it ideal for use on driveways, parking lots, and roadways, ensuring a tough, resilient surface that can handle both light and heavy traffic.

- DIY Friendly: Homeowners can easily apply Surface Bond without needing professional assistance. Its DIY-friendly formula simplifies the restoration process for any asphalt or concrete project.

- Versatility: Surface Bond works effectively on both small residential and large commercial projects, from driveways and patios to parking lots and sidewalks.

- Cost-Efficient: By prolonging the life of existing surfaces and preventing costly repairs or replacements, Surface Bond is a cost-efficient solution for maintaining and restoring concrete and asphalt.

- Enhanced Appearance: It maintains a clean, attractive appearance, offering a fresh, revitalized look for your surfaces.

With Armorpoxy's Surface Bond, you can turn and extend the life of your asphalt and concrete surfaces, giving them a fresh, ‘like-new’ appearance while adding protection against the elements.

Products

Surface Bond HD Color Asphalt and Concrete Coating - 4 Gal

Surface Bond Concrete Primer - 4 Gal