Epoxy Resin Flooring System

ArmorPoxy offers comprehensive epoxy resin flooring systems designed for superior protection, durability, and appearance in both residential and commercial settings. These multi-component systems include primers, build coats, additives, and high-performance top coats that work together to outperform basic epoxy paints.

Products

Job on a Pallet - Commercial Epoxy System - ArmorPoxy II 2-Layer - Per Sq Ft - Low & STD VOC

Job on a Pallet - Commercial Epoxy System - ArmorUltra 3-Layer - Per Sq Ft - Low & STD VOC

ArmorUltra Military Grade Topcoat

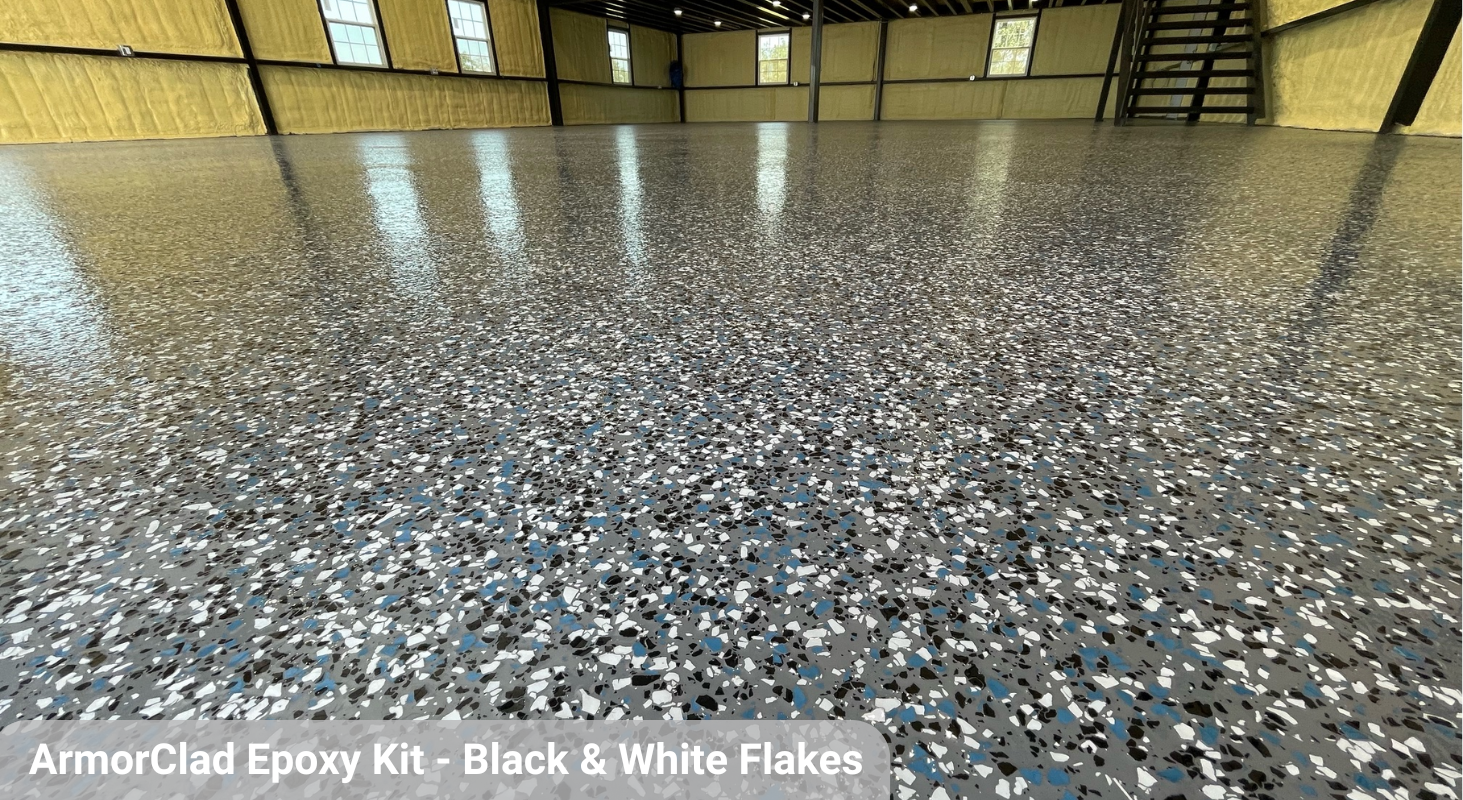

ArmorClad Epoxy Kit - Full Flake Broadcast Kit - 4-Layers - 300, 600, 900 Sq Ft

Professional Concrete Floor Solutions: Epoxy for Concrete & More

When transforming bare concrete into attractive, durable surfaces, property owners deserve options that deliver both performance and aesthetics. At ArmorPoxy, we offer advanced coating solutions, including epoxy paint for concrete that provides exceptional durability, stunning visual appeal, and superior value. Our epoxy floors for concrete applications are designed for both residential and commercial spaces, delivering long-lasting protection that ordinary paint simply cannot match.

Concrete floors present unique challenges - they're porous, susceptible to dusting, and can absorb stains and chemicals. High-quality epoxy coatings address these issues by creating a seamless, non-porous surface that resists damage while enhancing the appearance of your space. Whether for a home garage, retail establishment, manufacturing facility, or warehouse, our solutions transform ordinary concrete into extraordinary surfaces that withstand the test of time.

Comprehensive Epoxy Resin Flooring Systems

For environments requiring the ultimate in protection and appearance, our comprehensive epoxy resin flooring systems deliver unmatched performance. These complete epoxy floors for concrete provide engineered protection for even the most demanding applications.

ArmorPoxy’s professional epoxy floors for concrete typically involve multiple components working together:

- Deep-penetrating primers that create optimal bonding and address potential moisture issues

- Build coats that provide primary impact resistance and level uneven surfaces

- Performance-enhancing additives for slip resistance, chemical protection, or decorative effects

- High-performance top coats that enhance UV stability, chemical resistance, and wear characteristics

The synergy between these components creates a complete epoxy resin flooring system that far outperforms basic coatings. For industrial environments facing chemical exposure, heavy equipment traffic, or frequent cleaning, these engineered systems provide the optimal balance of protection and appearance. Healthcare facilities, food processing plants, and manufacturing operations particularly benefit from the seamless, sanitary surface that our epoxy resin flooring systems create.

The ArmorClad Advantage: Superior Epoxy Floor for Concrete

While many consumers search for simple epoxy paint for concrete, our ArmorClad Epoxy Kit offers significantly more advanced protection. Unlike conventional paint that merely sits on the surface, ArmorClad creates a chemical bond with the substrate, resulting in superior adhesion and exceptional resistance to chemicals, impacts, and abrasion.

What makes ArmorClad stand out in the concrete coating market? Our formulation features 100% solids—meaning there are no solvents to evaporate, resulting in a thicker, more durable finish. This professional-grade solution provides up to 3-5 times the thickness of water-based products, delivering remarkable longevity even in challenging environments like garages, workshops, and commercial spaces.

When comparing options for concrete floor protection, it's important to understand that not all epoxy products offer the same level of performance. Standard epoxy paint for concrete available at many home improvement stores often contains significant amounts of water or solvents, resulting in a thinner coating that may not withstand heavy use. Our ArmorClad system provides industrial-grade protection in a format accessible to both professionals and serious DIY enthusiasts.

ArmorClad's professional-grade formulation ensures maximum build thickness and performance. The result is not just a beautifully coated floor, but one that stands up to decades of demanding use.

Job on a Pallet: The Ultimate Epoxy Resin Flooring System

Our comprehensive Job on a Pallet kits represent the pinnacle of epoxy resin flooring systems, providing everything needed for large-scale concrete floor transformations in one convenient package.

Each Job on a Pallet includes precisely measured quantities of all system components—along with preparation materials, application tools, and detailed instructions. This pre-engineered epoxy resin flooring system eliminates guesswork about quantities and compatibility, ensuring each component works together as a cohesive system.

For facilities managers, contractors, or ambitious DIYers tackling commercial projects, warehouses, or larger residential applications, this all-in-one epoxy resin flooring system simplifies logistics while guaranteeing professional-quality outcomes.

What specific challenges does Job on a Pallet address? Many commercial flooring projects struggle with inconsistent results when materials are sourced from multiple suppliers or when quantities are improperly calculated. Our comprehensive approach ensures that you receive exactly what's needed for your specific square footage, with precisely matched components designed to work together. This system-based approach is particularly valuable for projects that can't afford failures or delays due to material incompatibility or shortages.

Clear Epoxy Resin for Concrete Floors: Decorative Excellence

Among our most visually striking options, clear epoxy resin for concrete floors offers unique aesthetic possibilities that standard colored systems can't match. These specialized formulations allow for:

- Showcasing stained or decorated concrete beneath a protective clear layer

- Encapsulating decorative elements like color flakes, metallic pigments, or embedded objects

- Creating high-build, glass-like finishes with exceptional depth and gloss

- Establishing effective moisture barriers while maintaining visual appeal

The versatility of clear epoxy resin for concrete floors makes it particularly valuable for retail environments, showrooms, restaurants, and high-end residential applications where visual impact is paramount. Many designers and architects specify these systems when they want to create truly custom flooring experiences that combine artistry with durability.

ArmorPoxy’s professional-grade clear epoxy resin for concrete floors offers exceptional clarity and UV stability, minimizing the yellowing that can affect inferior products. Advanced application techniques help prevent bubble formation that often plagues DIY clear coatings. Despite their stunning visual qualities, our clear epoxy resin for concrete floors doesn't sacrifice performance—with proper top coating, these systems provide the same durability as our pigmented options.

Polished Concrete: A Premium Alternative

For property owners interested in a different aesthetic, professionally polished concrete offers another premium option. This process mechanically refines the existing concrete surface through progressive diamond grinding, chemical densification, and protective sealing.

While different from our epoxy resin flooring systems, polished concrete delivers its own distinctive benefits:

- Showcases the natural characteristics of the concrete slab

- Provides excellent abrasion resistance for high-traffic areas

- Creates a sustainable solution that utilizes the existing material

- Offers a modern, industrial-inspired aesthetic that many designers prefer

The polished concrete process involves progressively refining the concrete surface using diamond abrasives of increasing fineness. Chemical densifiers penetrate the surface, reacting with free lime to increase hardness and durability. The result is a smooth, reflective surface that requires minimal maintenance while offering excellent slip resistance even when wet.

Polished concrete has gained significant popularity in retail environments, educational facilities, and modern office spaces where its distinctive appearance and sustainable credentials align with contemporary design sensibilities. As an alternative to applying epoxy paint for concrete or installing comprehensive coating systems, polished concrete maintains the authentic character of the original material while dramatically improving its performance characteristics.

Professional Installation Matters

Whether you choose our DIY-friendly ArmorClad Epoxy Kit or opt for a comprehensive Job on a Pallet system, proper installation is crucial to long-term performance. As experienced epoxy flooring professionals, we've engineered our products for successful application when our guidelines are followed.

The professional installation process includes:

- Thorough concrete evaluation for moisture, surface condition, and contaminants

- Proper surface preparation through diamond grinding, shot blasting, or chemical cleaning

- Strategic primer application to establish a strong foundation

- Precise base coat application with optional decorative elements

- Careful top coat application to seal and protect the entire system

Each of these steps is critical to the long-term success of your epoxy resin flooring system. Surface preparation, in particular, is often the determining factor between a floor that lasts for decades and one that experiences premature failure. Our preparation protocols exceed industry standards, ensuring that the concrete substrate is properly profiled to accept the epoxy coating system. We address issues like existing coatings, oil contamination, and surface laitance that might otherwise compromise adhesion.

What makes our approach superior? Our epoxy paint for concrete and epoxy resin flooring systems are engineered to work harmoniously together, eliminating compatibility concerns. Our comprehensive instructions ensure even first-time users understand proper techniques, while our expert team provides technical support throughout your project.

Choosing the Right Epoxy Floors for Concrete

Selecting the appropriate epoxy floors for concrete involves considering several important factors:

- Traffic patterns and usage intensity

- Potential chemical exposure or specific resistance requirements

- Aesthetic goals and desired appearance

- Budget considerations and long-term value

- Installation timeframe and schedule constraints

Different environments demand different performance characteristics from epoxy floors for concrete. A restaurant kitchen, for example, requires exceptional chemical resistance and slip protection, while a retail showroom might prioritize aesthetic impact and ease of cleaning. Manufacturing facilities often need resistance to specific chemicals and heavy load capacity, while residential garages benefit from protection against automotive fluids and hot tire pickup resistance.

ArmorPoxy’s technical team excels at matching specific performance requirements to the appropriate epoxy resin flooring system components. Rather than offering one-size-fits-all solutions, we analyze your unique needs and recommend systems engineered specifically for your application. This consultative approach ensures you receive exactly the right balance of protection, appearance, and value for your specific environment.

As experienced epoxy flooring professionals with expertise in polished concrete as well, we can help evaluate these factors and recommend the optimal system for your specific needs—whether that's our ArmorClad Epoxy Kit for residential applications, a comprehensive Job on a Pallet system for commercial settings, or a custom solution designed for your unique requirements.

Maintaining Your Epoxy Floors and Polished Concrete

One of the most significant advantages of both our epoxy resin flooring systems and polished concrete is their minimal maintenance requirements compared to traditional flooring materials.

For epoxy-coated concrete floors:

- Regular dust removal prevents abrasive wear

- Periodic cleaning with pH-neutral products preserves appearance

- Prompt spill cleanup maintains surface integrity

- Physical protection prevents unnecessary scratching

For polished concrete floors:

- Regular dust mopping removes particulates that could scratch the surface

- Weekly cleaning with appropriate pH-neutral cleaners maintains shine

- Annual application of stain protectors extends performance

- Immediate attention to chemical spills prevents potential etching

The minimal maintenance requirements of both epoxy floors for concrete and polished concrete represent one of their most significant advantages over traditional flooring materials.

With proper care, residential epoxy floors for concrete typically maintain their appearance for years before a refresh coat might be desired. Commercial environments may require maintenance coats more frequently, but the underlying epoxy paint for concrete system often remains structurally sound for decades.

Frequently Asked Questions About Concrete Floor Coatings

- Is epoxy paint suitable for outdoor concrete?

- Standard epoxy formulations are designed primarily for interior use, as UV exposure can cause yellowing over time. For exterior concrete, we recommend our specialized UV-resistant systems that provide superior weather resistance.

- Can epoxy be applied over existing concrete coatings?

- While possible in some cases if the existing coating is well-bonded, we generally recommend complete removal of existing materials to ensure direct bonding with the concrete substrate for optimal performance and longevity.

- How does your epoxy flooring handle moisture issues in concrete?

- For projects with known moisture concerns, we offer specialized moisture mitigation systems that can be installed beneath our standard epoxy resin flooring systems to prevent adhesion failures and blistering.

- Is epoxy flooring slippery when wet?

- We offer various anti-slip additives and textured finishes that provide appropriate traction without compromising cleanability or appearance. Moreover, our kits come with non-skid additive for enhanced safety. Contact our support team

- What makes your epoxy flooring professional approach different?

- Our specialized expertise in substrate evaluation, preparation techniques, and application methods directly impacts system performance. As dedicated epoxy flooring professionals, our experience with various formulations and environmental conditions allows us to anticipate and address potential issues before they affect your finished floor.

- How soon can I use my floor after installation?

- Depending on the specific system, light foot traffic is typically possible within 24 hours, while full vehicular or heavy traffic may require 72 hours or more. Temperature and humidity can affect curing rates, with warmer conditions generally accelerating the process. Our technical team provides specific guidance for each installation to ensure optimal results.

Transform Your Concrete with ArmorPoxy's Premium Solutions

Whether you're seeking a system that outperforms typical epoxy paint for concrete, a comprehensive epoxy resin flooring system, or guidance on polished concrete applications, ArmorPoxy provides industry-leading products and support to ensure exceptional results.

As established epoxy flooring professionals with decades of experience in both epoxy floors for concrete and polished concrete, we understand that every project has unique requirements. Our ArmorClad Epoxy Kit and comprehensive Job on a Pallet systems are engineered to deliver outstanding performance, aesthetics, and value that stand the test of time.

Our commitment to excellence has made ArmorPoxy the trusted choice for facilities ranging from residential garages to major manufacturing plants, government installations, healthcare facilities, and educational institutions nationwide.

Ready to transform your concrete floors from ordinary to extraordinary? Explore our complete range of solutions—from professional-grade epoxy paint for concrete alternatives to complete epoxy resin flooring systems—and discover why discerning property owners, contractors, and businesses nationwide trust ArmorPoxy for their concrete flooring needs.