One of the most common questions we get is “Why are there bubbles in my epoxy floor?”. Let’s take a look at why this occurs and how to address the issue when it happens.

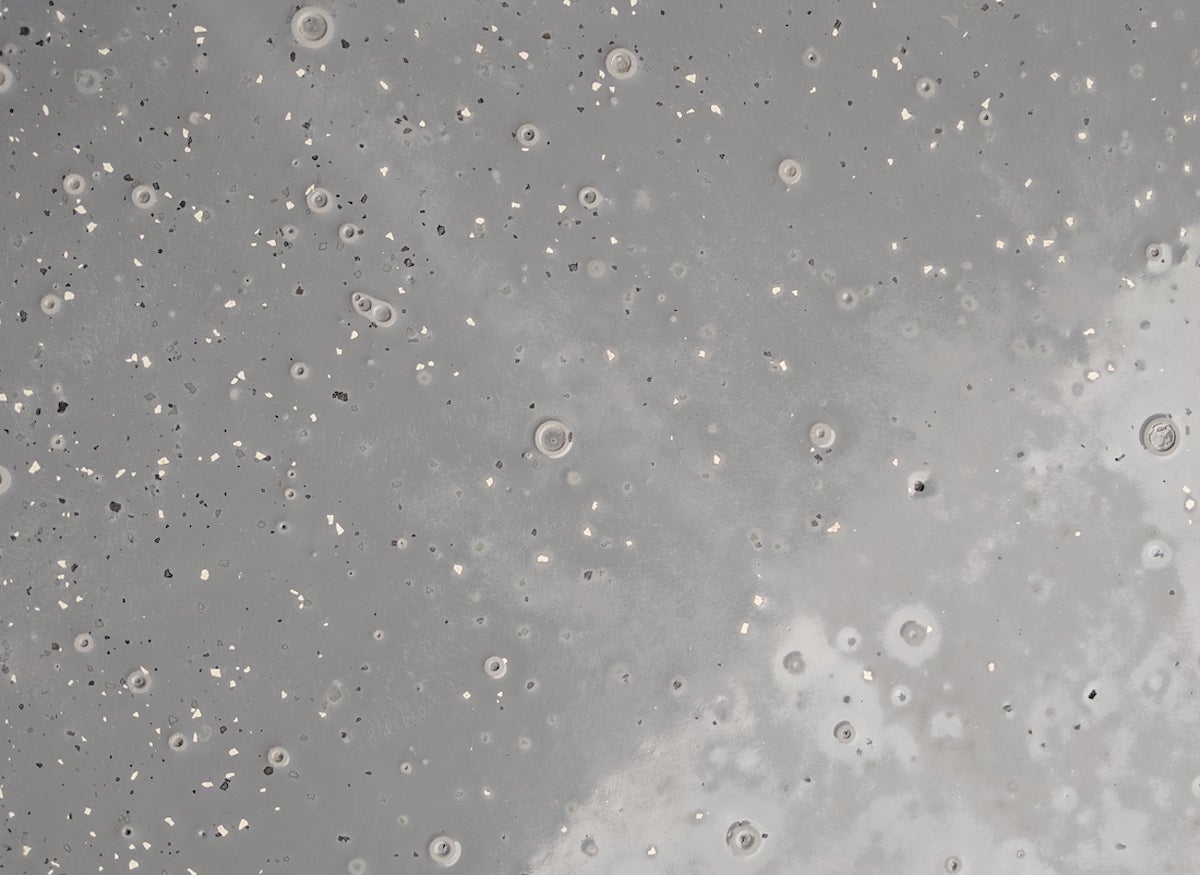

Air moves in and out of concrete with changes in temperature. When air gets trapped or gasses from the concrete substrate release they can create tiny bubbles, pinholes, blisters and craters in the epoxy coating. This process is called outgassing.

The main function of an epoxy coating or flooring systems in general is to provide a barrier of entry to outside liquids, chemicals and other items that enter the floor. Any voids or bubbles in a coating can greatly affect the integrity of the coating so it’s important to address these issues as they occur.

Why Does Outgassing Occur?

Outgassing that results in bubbles, pinholes and craters is a result of residual silicone, oil, or grease that is left on the surface of the flooring before applying an epoxy coating. When applied on top of these residuals there is an increase in temperature, and the epoxy reacts with the residual oils and creates pinhole faults.

Outgassing can be caused by a change in the room’s temperature as the epoxy is curing, which is the process in which the epoxy is hardening. The change in a room’s temperature may result in bubbles forming in the layers of the epoxy. These bubbles continue to form, expand, and rise until they are released from the surface. Additionally any changes in humidity can prevent the coating to not set which can lead to bubbles forming. These tiny bubbles are essentially trapped air or moisture.

Other causes of faults are contingent on the preparation of your epoxy products. One is engaging in a high powered mixing of the resin and hardener solutions which causes more bubbles to emerge. Using excessive solvent may produce an overflow of evaporation, which leaves pinholes in the surface of the epoxy. These causes can be avoided with a careful application of each epoxy product and by retaining a consistent temperature throughout the application process.

Understanding the Issue:

- Air Movement and Outgassing:

- Bubbles often form due to air moving in and out of concrete as temperatures change.

- Gasses trapped in the substrate can create pinholes, blisters, and craters during the curing process.

- Impact on Coating Integrity:

- Bubbles and voids compromise the epoxy's ability to protect against liquids and chemicals, risking floor durability.

Causes of Bubbles:

- Residual Contaminants:

- Silicone, oil, or grease on the surface can cause reactions with the epoxy, leading to pinholes.

- Temperature Changes:

- Fluctuations during curing can cause trapped air and moisture to expand, forming bubbles.

- Mixing and Application Techniques:

- Over-mixing resin and hardener increases bubble formation.

- Excessive solvent evaporation can lead to surface pinholes.

How To Get Rid Of Bubbles

There are a number of methods to fix epoxy bubbles and pinholes. While it's impossible to predict bubble formation, being prepared with effective techniques allows for quick resolution and maintains the integrity of your epoxy coating. We have found the below methods to be most effective when working with our coatings.

Hot Air Gun

While the epoxy is drying you can apply heat that will draw the air bubbles to the surface. We do not suggest using a blow torch and to avoid using any flames as most epoxies are flammable.

To remove the bubbles take a hot air gun or blow dryer directly above the bubbles. This will help them to vent out and fill with resin. You can accomplish getting rid of multiple bubbles relatively quickly. Just be sure to exhaust air rather than blowing with wall fans.

Spiked Roller

Use a porcupine or spiked roller to pop the bubbles that are beginning to form. This can help to prevent outgassing from occurring and will allow the coating to fill into those areas affected. This will also help to prevent bubbles forming in subsequent layers.

There is no way to predict if there will or won’t be bubbles once a coating has been poured. The best thing you can do is be prepared for when this does happen because inevitably it will. But do not forget these issues can be resolved!