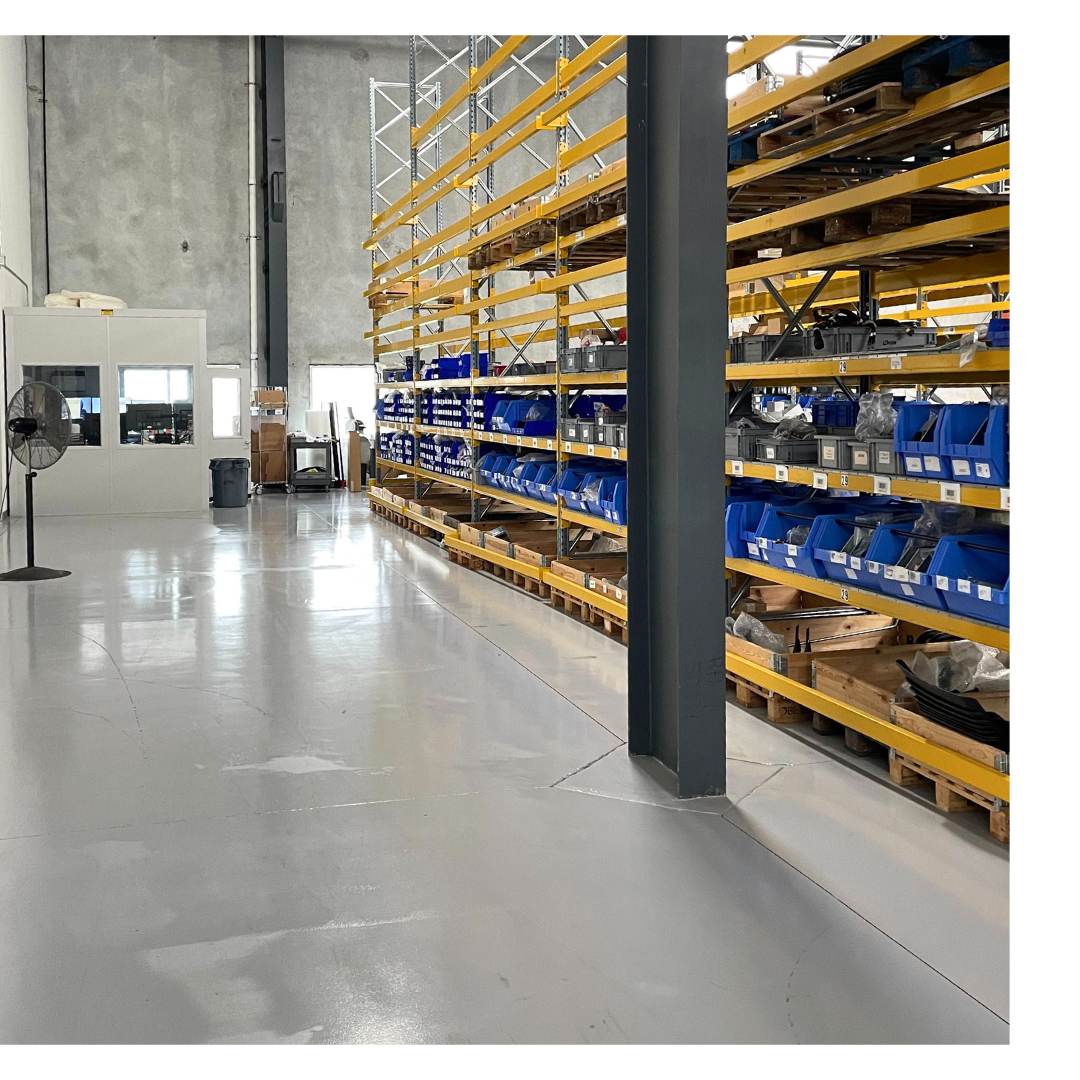

Warehouse Floor Coatings

ArmorPoxy warehouse floor coatings and warehouse flooring is ideal for warehouses, line striping, forklift traffic, loading docks, packaging & shipping areas, public & employee areas and virtually any similar type of commercial or industrial usage. Save up to 80% over a contractor installed floor. ArmorPoxy specializes in a wide array of warehouse flooring and commercial floor coatings for virtually any application. Over 50,000,000 square feet sold! All ArmorPoxy warehouse floor systems are USDA approved for food area use and are highly resistant to forklift traffic and designed to last many, many years. Our warehouse floor coating systems can also be re-topcoated at any time easily and inexpensively.

ArmorPoxy is a premier manufacturer and supplier of advanced floor coating solutions tailored for a variety of commercial and industrial applications. Their product lineup addresses the flooring needs of diverse environments, including warehouses, factories, commercial kitchens, kennels, airplane hangars, shops, garages, laboratories, and areas requiring electrostatic dissipative flooring or corrosion resistance. ArmorPoxy’s coatings are designed for durability, ease of installation, and longevity, far outperforming conventional floor paints.

ArmorPoxy is a premier manufacturer and supplier of advanced floor coating solutions tailored for a variety of commercial and industrial applications. Their product lineup addresses the flooring needs of diverse environments, including warehouses, factories, commercial kitchens, kennels, airplane hangars, shops, garages, laboratories, and areas requiring electrostatic dissipative flooring or corrosion resistance. ArmorPoxy’s coatings are designed for durability, ease of installation, and longevity, far outperforming conventional floor paints.

Our warehouse floor coatings are USDA-approved, making them suitable for food areas and capable of resisting forklift traffic, dirt, heavy equipment, and more. These coatings are built to last many years, with the added benefit of being easily re-topcoated for a refreshed surface at any time. This flexibility allows warehouse managers to keep their floors looking pristine without expensive overhauls.

For warehouses, which endure substantial wear from machinery, frequent traffic, and minimal cleaning, ArmorPoxy recommends its ArmorPoxy II and ArmorUltra systems. These are specifically engineered for high durability and can withstand the rigors of heavy industrial use. In addition to these, ArmorPoxy provides solutions for floors that are exposed to corrosive substances or have sustained damage, complemented by a comprehensive range of repair products like epoxy mortars, crack fillers, and urethane mortars.

ArmorPoxy's industrial floor coatings vary significantly in thickness, offering solutions ranging from the more economical 7 mil ArmorPoxy II system to the robust Urethane Mortar High build system, which can reach up to 250 mils in thickness. This variety ensures that there is an ArmorPoxy product suitable for nearly any commercial flooring scenario, with options available to match specific performance requirements and budgetary constraints.

Job on a Pallet Kits

ArmorPoxy invented the ‘Job on a Pallet‘ kit system for easy self-installation of epoxy floors. We offer a wide variety of Job on Pallet kits for virtually all of our warehouse floor coating systems including ArmorPoxy II, ArmorUltra, and UltraFast. Each Job on a Pallet Kit includes prep/etching solution, industrial rollers and frames, mixers mixing buckets, nonskid additive, coatings and easy to follow instructions. All ArmorPoxy warehouse coatings packaging is color-coded and properly marked for easy mixing and application.

- Durability: ArmorPoxy coatings are built to withstand the harsh conditions often found in warehouses. They are designed for high durability, ensuring they can handle the weight of heavy machinery and frequent foot traffic without succumbing to wear. Our coatings are highly resistant to corrosion, abrasion, and general wear, ensuring floors maintain their integrity over time.

- Versatility: These coatings cater to a wide range of commercial and industrial applications. Whether you’re in a warehouse, factory, commercial kitchen, garage, or laboratory, ArmorPoxy offers flooring solutions tailored to your specific needs. Available in both solid colors and decorative fleck finishes, ensuring you can match your space’s aesthetics.

- Repair Options: In the event of damage, ArmorPoxy provides an extensive selection of repair products. This includes epoxy mortars, crack fillers, and urethane mortars, allowing for quick and efficient restoration of your flooring to maintain its functionality and appearance.

- Thickness Variety: ArmorPoxy offers a range of coating systems varying in thickness to meet diverse performance requirements. From the economical 7 mil ArmorPoxy II system to the best Urethane Mortar High Build system, which can reach up to 250 mils in thickness, you can select the best solution to fit your budget and application needs.

- Self-Installation Kits: Simplifying the installation process, ArmorPoxy has introduced the innovative ‘Job on a Pallet’ kits. These kits include everything needed for a successful DIY installation: prep and etching solutions, industrial rollers, mixing buckets, non-skid additives, and easy-to-follow instructions. This feature allows businesses to save on labor costs while achieving professional results.

- Cost-Effective: Save up to 80% compared to professional installation with our easy-to-apply, long-lasting coating systems.

For a durable, customizable, and affordable warehouse flooring solution, choose ArmorPoxy to meet all your industrial flooring needs. Contact our support team and place your order today!

Products

Job on a Pallet - Commercial Epoxy System - ArmorUltra 3-Layer - Per Sq Ft - Low & STD VOC

6.5 mm - T-Joint SupraTile - Coin or Textured - $4.97/Sq Ft

Polyaspartic - 2 Gal Clear / Colored