Garage Flooring Solutions

Upgrade your garage with durable, professional-grade flooring solutions. From easy DIY epoxy kits to advanced polyaspartic systems and interlocking tiles, ArmorPoxy has the perfect option for every space and budget.

Products

Job on a Pallet - Commercial Epoxy System - ArmorPoxy II 2-Layer - Per Sq Ft - Low & STD VOC

Job on a Pallet - Commercial Epoxy System - ArmorUltra 3-Layer - Per Sq Ft - Low & STD VOC

5.5 mm - Hidden Joint SupraTile - Slate - $4.54/Sq Ft

5.5 mm - Hidden Joint SupraTile - Leather - $4.44/Sq Ft

4.5 mm - Dovetail SupraTile - Diamond - $3.25/Sq Ft

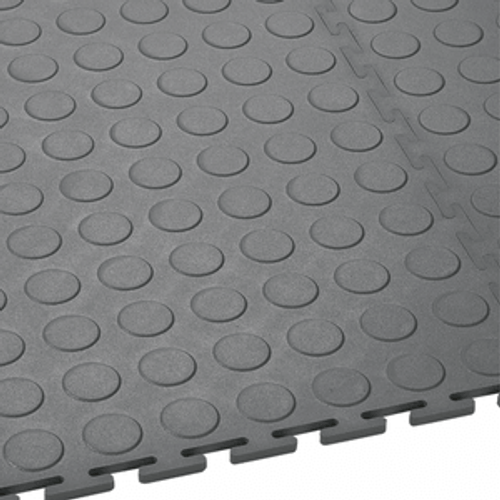

4.5 mm - T-Joint SupraTile Coin or Textured - $3.25/Sq Ft

ArmorClad Epoxy Kit - Full Flake Broadcast Kit - 4-Layers - 300, 600, 900 Sq Ft

Polyaspartic Floor Kit - Fast Drying - Indoor & Outdoor - Up to 500 SQ FT

Your garage deserves more than concrete stains and tire marks. Whether you're looking to protect your investment, enhance your home's value, or create a workspace you can be proud of, the right flooring solution makes all the difference. From professional-grade coatings to innovative tile systems, modern garage flooring options offer durability, style, and functionality that transforms ordinary spaces into extraordinary ones.

Why Upgrade Your Concrete Surface?

Many homeowners underestimate the transformative impact that quality garage flooring can have on their daily lives. Raw concrete is porous, prone to staining, and difficult to maintain. Oil spills, tire marks, and general wear create an unsightly surface that's nearly impossible to clean effectively. Professional garage floor painting and coating solutions address these challenges while providing additional benefits that extend far beyond appearance.

A properly installed floor coating creates a protective barrier that shields your concrete from moisture damage, chemical spills, and thermal cycling. This protection is particularly important in regions with harsh winters, where road salt and freeze-thaw cycles can cause significant deterioration to unprotected concrete surfaces.

What Makes Professional Coatings Different?

The distinction between professional-grade products and consumer alternatives becomes apparent in both application and longevity. Professional systems typically feature higher solids content, superior adhesion properties, and enhanced chemical resistance. These characteristics translate to longer-lasting performance and better value over time.

When searching for reliable garage floor painting solutions in your area, it's essential to understand that not all products are created equal. Professional-grade systems undergo rigorous testing for durability, chemical resistance, and adhesion strength. This testing ensures that your investment will withstand the demands of daily use while maintaining its appearance and protective properties.

ArmorClad Epoxy Kits: Professional Results Made Accessible

ArmorClad Epoxy Kits represent the perfect balance of professional performance and user-friendly application. These comprehensive systems include everything needed for a successful installation, from surface preparation materials to topcoat application tools. The two-component epoxy formulation provides exceptional durability and chemical resistance, while the included decorative flakes add visual appeal and slip resistance.

Understanding Different Flooring Technologies

Modern garage flooring encompasses several distinct technologies, each offering unique advantages for specific applications and preferences. Understanding these differences helps homeowners make informed decisions that align with their needs, budget, and timeline.

How Do Epoxy Systems Work?

Epoxy coatings cure through a chemical reaction between resin and hardener components, creating a cross-linked polymer structure that bonds permanently to properly prepared concrete. This chemical bond is significantly stronger than mechanical adhesion alone, providing exceptional durability and longevity. The curing process typically takes several hours to complete, during which the coating transforms from a liquid application to a hard, glossy surface.

Professional epoxy systems offer superior performance compared to single-component alternatives. The chemical curing process creates a coating that's resistant to hot tire pickup, chemical stains, and mechanical damage. When properly applied over correctly prepared surfaces, garage floor painting with professional epoxy systems can last decades with minimal maintenance requirements.

What Are the Advantages of Polyaspartic Technology?

Polyaspartic coatings represent the latest advancement in floor coating technology, offering rapid cure times and exceptional durability. These systems can often be applied and ready for vehicle traffic within 24 hours, making them ideal for homeowners who need quick turnaround times.

Polyaspartic Floor Kits: Next-Generation Performance

Polyaspartic Floor Kits deliver professional-grade results with accelerated installation timelines. These systems cure rapidly while maintaining excellent flow and leveling characteristics. The resulting surface offers superior UV stability, chemical resistance, and mechanical properties. Unlike traditional epoxy systems, polyaspartic coatings maintain their clarity and color stability when exposed to sunlight, making them suitable for garages with windows or door openings.

The rapid cure characteristics of polyaspartic systems don't compromise performance. In fact, these coatings often exceed the mechanical and chemical resistance properties of traditional epoxy systems while offering the added benefit of UV stability. This makes them particularly suitable for spaces that receive natural light or for homeowners who want the option to keep garage doors open during the day.

Professional Installation vs. DIY Approaches

The success of any garage floor painting project depends heavily on proper surface preparation and application technique. While some homeowners successfully complete DIY installations, understanding the complexity involved helps inform decision-making about whether to proceed independently or engage professional services.

What Does Proper Surface Preparation Involve?

Concrete preparation is the most critical factor in coating performance and longevity. The surface must be clean, dry, and properly profiled to ensure adequate adhesion. This process typically involves degreasing, crack repair, and mechanical abrading or acid etching to create the proper surface profile.

Professional preparation often includes diamond grinding or shot blasting to achieve optimal surface profile. These methods remove surface contaminants, open the concrete pores, and create the mechanical anchor pattern necessary for long-term adhesion. Inadequate preparation is the leading cause of coating failure, regardless of product quality.

Why Choose Professional Application?

Professional applicators bring specialized equipment, experience, and material knowledge that's difficult to replicate in DIY garage floor painting installations. They understand how environmental conditions affect application and curing, can identify and address substrate issues, and have access to commercial-grade preparation equipment. Most importantly, professional installations typically include warranties that protect your investment.

Can Homeowners Achieve Professional Results?

Motivated homeowners can achieve excellent results with proper planning, preparation, and attention to detail. Success requires understanding material characteristics, environmental conditions, and application techniques. High-quality kits that include detailed instructions and technical support significantly improve the likelihood of successful DIY installation.

The key to successful DIY garage floor painting lies in patience and preparation. Rushing the process or skipping steps almost invariably leads to disappointing results. Homeowners who invest time in understanding the process and follow manufacturer instructions carefully can achieve results that rival professional installations.

Job on a Pallet: Complete Project Solutions

Job on a Pallet packages represent comprehensive project solutions that include all materials, tools, and accessories needed for successful installations. These packages eliminate guesswork about quantities and compatibility while ensuring that all components work together optimally. The included technical support provides additional confidence for DIY installers tackling their first coating project.

Maintenance and Long-Term Performance

Properly installed garage flooring requires minimal maintenance while providing decades of reliable service. Understanding basic care requirements helps maximize the lifespan and appearance of your investment while avoiding practices that might compromise performance.

How Do You Maintain Coated Floors?

Regular maintenance consists primarily of routine cleaning with mild detergents and periodic inspection for damage. The non-porous surface created by quality coatings resists staining and makes cleanup simple. Most spills can be removed with basic household cleaners, while stubborn stains may require specialized degreasers.

Avoiding harsh chemicals and abrasive cleaning methods preserves the coating's appearance and protective properties. While professional coatings offer excellent chemical resistance, unnecessary exposure to aggressive solvents or acids should be avoided. Simple preventive measures, such as using drip pans under vehicles and promptly cleaning spills, maintain optimal appearance with minimal effort.

What About Repairs and Touch-ups?

Professional-grade coatings are designed to withstand normal garage use without requiring frequent repairs. However, severe impacts or sharp objects can occasionally damage the surface. Most minor damage can be repaired using touch-up materials that match the original installation.

The key to successful repairs is addressing damage promptly before it can expand or allow moisture intrusion. Small chips or scratches can typically be filled and blended seamlessly, while larger areas may require more extensive repair procedures. Maintaining a small quantity of original material for future touch-ups is always recommended.

Alternative Solutions: Interlocking Tile Systems

While coated systems dominate the garage flooring market, interlocking tile systems offer unique advantages for specific applications and preferences. These systems provide immediate gratification with no curing time, complete reversibility, and the ability to replace individual sections if needed.

When Do Tiles Make Sense?

Interlocking tile systems excel in situations where permanent installation isn't desired or possible. Rental properties, frequently reconfigured spaces, or garages with existing damage that makes coating application challenging are all good candidates for tile systems.

SupraTile Interlocking Systems: Flexible Solutions

SupraTile interlocking systems provide professional appearance with installation flexibility. These high-quality tiles install quickly without adhesives or special tools, making them ideal for temporary installations or spaces that require frequent reconfiguration. The interlocking design creates a seamless appearance while allowing individual tile replacement if needed.

Modern interlocking tiles have evolved significantly from early versions, now offering improved durability, better aesthetics, and enhanced functionality. Quality systems provide excellent chemical resistance and can withstand the weight of vehicles without deflection or damage.

Choosing the Right Solution for Your Needs

What Factors Should Guide Your Decision?

Usage patterns significantly influence garage floor painting selection. Garages used primarily for vehicle storage have different requirements than those serving as workshops, gyms, or multi-purpose spaces. Heavy equipment, frequent chemical exposure, or high traffic volumes may necessitate more robust solutions than basic protection applications.

Climate considerations also play important roles in product selection. Regions with extreme temperature variations, high humidity, or frequent freeze-thaw cycles require coatings designed to handle these conditions without failure. UV exposure in garages with windows or frequent door opening may favor polyaspartic systems over traditional epoxy.

How Do You Find Quality Installation Services?

When searching for professional garage floor painting services near you, several factors distinguish quality contractors from less reliable alternatives. Look for businesses with established track records, proper licensing and insurance, and portfolios of completed projects. References from recent customers provide valuable insights into work quality and customer service.

Quality contractors should provide detailed written estimates that specify materials, preparation procedures, and warranty terms. They should be willing to discuss product options and explain why they recommend specific systems for your application. Beware of contractors who provide only verbal estimates or pressure you to sign contracts immediately.

Investment Value and Return Considerations

How Does Flooring Affect Property Value?

Real estate professionals consistently identify quality garage flooring as a feature that distinguishes properties in competitive markets. While the exact return on investment varies by location and market conditions, improved garages typically add value that approaches or exceeds the installation cost.

Beyond monetary considerations, quality flooring enhances daily living by creating cleaner, more pleasant spaces. The ability to use garages for multiple purposes—storage, workshops, exercise areas, or entertainment spaces—adds functional square footage to homes without expensive additions or renovations.

What About Maintenance Cost Savings?

Coated floors virtually eliminate the ongoing costs associated with cleaning and maintaining raw concrete. The sealed surface prevents oil penetration, eliminates dusting, and makes cleanup quick and easy. These benefits compound over time, resulting in significant savings in cleaning products, time, and effort.

The protective nature of quality coatings also prevents concrete deterioration that might otherwise require expensive repairs. Preventing moisture intrusion, chemical damage, and freeze-thaw cycling preserves the structural integrity of garage floors while avoiding costly concrete restoration projects.

Future Trends and Innovations

What's Next in Coating Technology?

Advances in polymer chemistry continue improving coating performance while simplifying application procedures. New formulations offer enhanced durability, faster cure times, and improved environmental characteristics. Some systems now cure properly at lower temperatures, expanding the installation season in colder climates.

Smart coating technologies that change color to indicate temperature, moisture, or chemical exposure are emerging from laboratory settings. While not yet commercially viable for residential applications, these innovations suggest exciting possibilities for future garage flooring solutions.

Environmental considerations increasingly influence product development, with manufacturers focusing on low-VOC formulations and sustainable raw materials. These improvements benefit both applicators and end users while supporting broader environmental responsibility goals.

The garage flooring market continues expanding as homeowners recognize the value and versatility these improvements provide. From basic protection to complete space transformation, modern solutions offer options that meet virtually any need, budget, or aesthetic preference. The key lies in understanding your specific requirements and selecting products and installation methods that deliver optimal results for your situation.

Whether you're planning a simple protective coating or a complete garage makeover, investing in quality garage floor painting materials and proper installation techniques ensures results that provide lasting satisfaction and value. The transformation achievable through professional garage flooring solutions continues to surprise homeowners who discover that their garage can become one of their favorite spaces.